Force spectroscopy technology

Impetux’s exclusive, patented force spectroscopy technology leads you where other force methods cannot

Our products represent a breakthrough in how optical tweezers force measurements are performed, enabling and making simple unprecedented experiments where traditional trap stiffness calibration fails:

- Direct force measurements: no calibrations needed.

- Simultaneous force measurements for multiple independent traps.

- Compatible with different imaging techniques including BrightField, epi-FL, TIRF or Confocal microscopy

- Force resolution <50 fN.

- Accuracy: typ. <5-10%.

- Accurate determination of sample position (typ. resolution: 1 nm).

- Measures laser power at the sample and ambient temperature.

- Easy installation and operation.

Force measurements on irregular & non-spherical objects.

Optical trapping forces can be measured on irregular & non-spherical objects such as micro-cylinders, rod-shaped bacteria or cellular structures like cell membranes.

Measure forces beyond the trap stiffness linear region.

Our unique force sensor allows measuring forces beyond the trap stiffness linear region (F=k·x) meaning that, for a given trapping laser power, higher forces can be applied and measured with respect to other standard methods what allows minimizing irradiation doses on your samples.

A force spectroscopy method independent of sample & medium properties.

Direct force measurements are independent of sample & medium properties and can be easily performed even inside complex viscoelastic media like living cells & tissues.

A force measurement instrument for optical tweezers based on the detection of light momentum changes

A unique optical tweezers force spectroscopy sensor based on light momentum analysis

The key of our technology is that it measures the force as a derived magnitude of the direction of propagation (momentum) of the laser trapping beam. The analysis of laser trapping light momentum changes provides a direct route to the force. Hence, unlike other systems based on regular back focal plane interferometry or video tracking our force sensor allows measuring forces without requiring any sample position tracking or any previous trap stiffness calibration. This gives our technology a key advantage for measuring forces in complex media like cells or biological tissues since no restrictions on the sample are imposed.

The Momentum method. Reliability, Accuracy & Repeatability

Initially developed by Carlos Bustamante’s lab (Berkeley University), the momentum method was originally applicable only to a counter-propagation optical trapping configuration where two counter propagating laser beams are used to compensate the axial (z-axis) scattering force of light. IMPETUX’s force sensing technology overcomes this limitation and allows implementing the momentum method for standard optical tweezers configuration force measurements.

Contrary to other existing commercial solutions, the calibration of our light momentum-based sensor is a one-time event since it is only dependent on the optical and electronic specs of the sensor itself. Made at factory, each sensor calibration is unique, constant and permanent. Direct force measurements are therefore possible without needing any prior calibration independently of sample and medium conditions with great accuracy and repeatability.

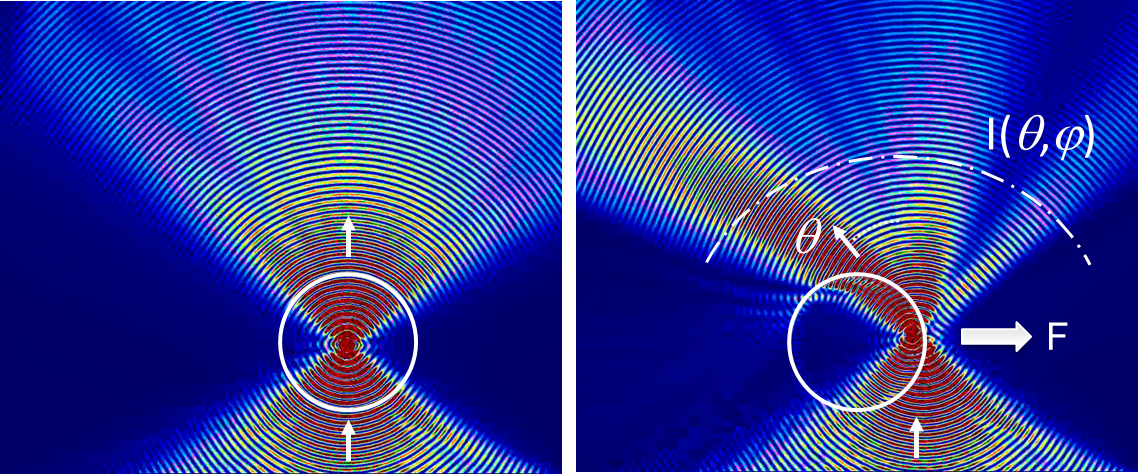

Simulation of the beam light propagation path for a trapped centered (left) and off-centered (right) microsphere. In the first case there is no net restoring force since the mean value of the forward scattered light deflection angle is zero. In the second case, <sinθ>≠0, and there is a net restoring force acting on the bead: F=n•P•<sinθ>/c.

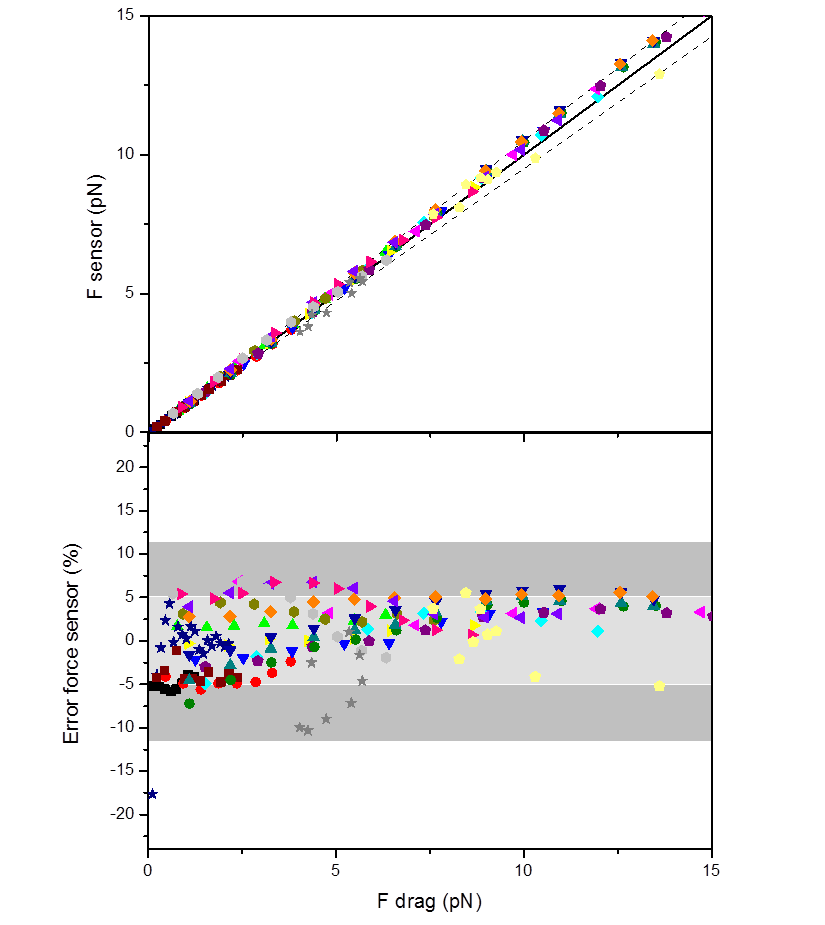

Measured force vs. theoretical force, derived from Stokes equation, for different samples and medium conditions (top) and relative errors for all data. Data colors and symbols refer to each different experimental conditions:

Samples: microspheres (d=0.5 – 5 µm, n=1.46 – 1.59), micro-cylinders (L=10 – 50 µm; d=5 µm, n=1.52) & purified lipid droplets (d=1-3 µm; n=1.52). Medium: pure water (n=1.333) and water like medium (n=1.348 – 1.364). Laser trapping: perfect Gaussian & aberrated beams.

The force sensor substitutes the illumination condenser, without affecting the imaging capabilities of the microscope. It can be installed in a very simple and fast way by a single user without any required expertise.

Adjustment of the sensor height is straightforward thanks to the integrated iris used as reference.

Easy installation & operation

Our force spectroscopy sensor can be installed and set in operation through a simple procedure even by non-expert users. Check the following videos for instrument installation and height adjustment. To see the force sensor in action check the video demonstrations in the SENSOCELL product page and our applications pages!

.

Force spectroscopy sensor technical specifications

All our systems have been designed with the utmost quality in mind. High reproducibility in the results is provided thanks to the implementation of systematic routines in the operation of the force sensor. The sensors incorporate immersion optics for maximum signal sensitivity, especially when working with small samples or at low powers. The integrated analog and digital electronics, featuring high-resolution A/D converters ensure acquisition fidelity. A careful design guarantees mechanical stability and easy installation.

- Dual measurement mode: position calibration through back-plane interferometry and detection of light momentum for single movable traps.

- Straightforward installation and tuning routines ensure correct measurements and reproducibility (eyepiece with Bertrand lens incorporated or Centering Scope required).

- High Numerical-Aperture (NA=1.4) immersion optics. Optical design optimized for λ=1064 nm.

- Maximum laser power at the sample: 300 mW (Check with us different power ranges to fit your needs).

- Force resolution <50 fN.

- Position resolution: 1 nm (typ.).

- Integrated sensor noise over the whole bandwidth <0.1 pN (typ.).

- Temperature-compensated, duo-lateral position sensitive detector (PSD) (max. sampling frequency 100 kHz).

- Up to 100 kHz, 18-bit, analog-to-digital conversion.

- Direct PC communication through Hi-speed USB 2.0 port.

- Highly-regulated, low-noise linear power supply (models with 100/120/220/240 VAC- 50/60 Hz available).

- Acquisition software and LabVIEW libraries included.

- Dimensions of the sensor head (L x H x W): 22 x 18 x 11 cm.

Would you like a DEMO?

Download SENSOCELL brochure